Are You Tough Enough for the Aseptic Room?

Regular readers of Kilmer House have read about the aseptic, or sterile conditions that Johnson & Johnson maintained over 100 years ago in order to manufacture the first mass produced sterile surgical dressings and sterile sutures. So I thought it would be interesting to post some of the rules for our Aseptic Department from 1897: 112 years ago.

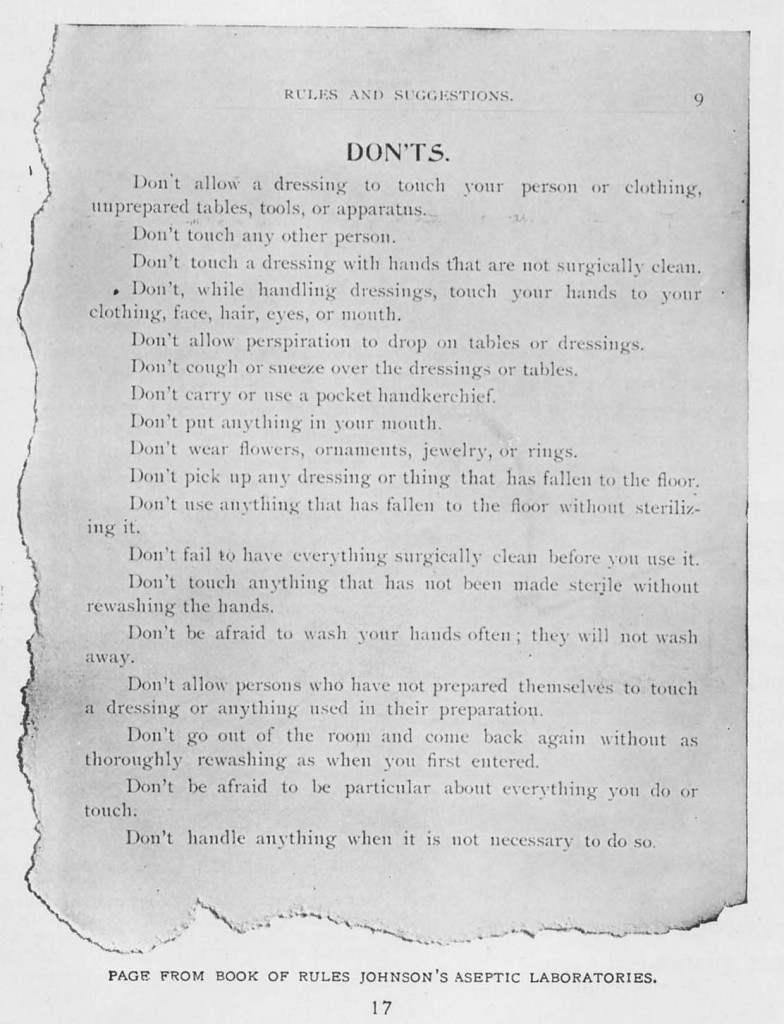

You Can’t Do That! A list of what not to do from 1897

Don’t allow a dressing to touch your person or clothing, unprepared tables, tools or apparatus.

Don’t touch any other person.

Don’t touch a dressing with hands that are not surgically clean.

Don’t, while handling dressings, touch your hands to your clothing, face, hair, eyes or mouth.

Don’t allow perspiration to drop on tables or dressings [Remember, this was before air conditioning!]

Don’t cough or sneeze over the dressings or tables.

Don’t carry or use a pocket handkerchief.

Don’t put anything in your mouth.

Don’t wear flowers, ornaments, jewelry or rings. [In case you’re wondering about this rule, many or most of the Aseptic Department employees were women.]

Don’t pick up any dressing or thing that has fallen to the floor.

Don’t use anything that has fallen to the floor without sterilizing it.

Don’t fail to have everything surgically clean before you use it.

Don’t touch anything that has not been made sterile without rewashing the hands.

Don’t be afraid to wash your hands often; they will not wash away.

Don’t allow persons who have not prepared themselves to touch a dressing or anything used in their preparation.

Don’t go out of the room and come back again without as thoroughly rewashing as when you first entered.

Don’t be afraid to be particular about everything you do or touch.

Don’t handle anything when it is not necessary to do so.

[Aseptic Dressings, Rules and Suggestions, Johnson & Johnson, late 1800s]

The Aseptic Department in 1903. Many of the employees in this most crucial and exacting department were women. In 1908, this included Nora H------, the Aseptic Department supervisor.

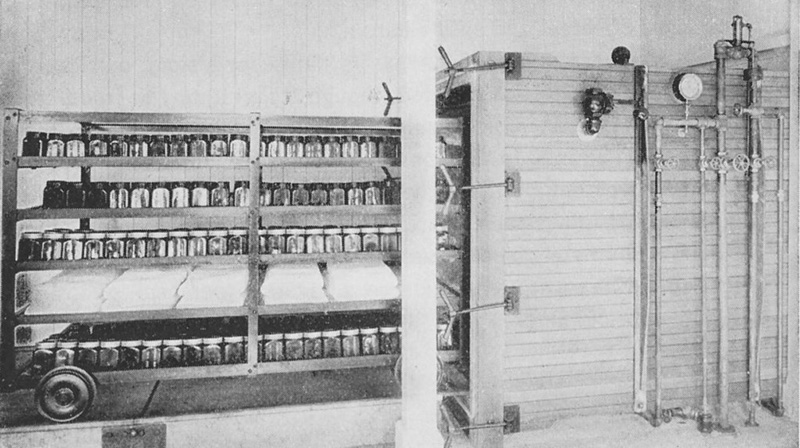

One of the Sterilizers, 1897

Here’s a 1908 description of the Company’s aseptic manufacturing facilities. The antiseptic laboratory contained a steam sterilizer, a sterilization method pioneered by Johnson & Johnson. It was connected with the aseptic finishing room which, according to scientific director Fred Kilmer (who oversaw the creation of these rooms) was “…the outcome of years of study in the preparation of surgical material.” [RED CROSS NOTES, Series VI, No. 6, New Brunswick, NJ 1908, p. 127] Plate glass (which could easily be kept germ free) formed the partitions for this room. The floor was made from hard wood, and the walls and woodwork were covered in smooth white enamel, as was the metal ceiling. The tables were enameled metal with glass tops so they could be disinfected.

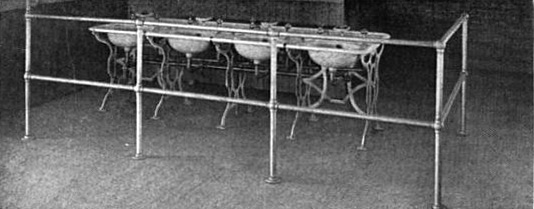

A corner of the Aseptic Department – you can see the glass topped enamel table

Here’s a further description:

“The walls and ceiling are glass smooth. The floors are filled and polished. There are no closets or shelving, no cracks or crevices to harbor dust or dirt. The furniture consists of glass-topped tables on iron frames, which allow effectual and easy cleaning. Everything, whatsoever may be its nature or history, outside of this room, is considered as infected (though in fact it may be free from germ life); it is, therefore, disinfected before being taken into the room. The entrance to this room is through an anteroom, which is a disinfecting station of the highest type. Through this quarantine all persons and things pass before entering the aseptic room. The inanimate objects pass through the sterilizer elsewhere described. The operatives undergo a vigorous personal cleansing and change of clothing.” [Asepsis Secundum Artem, Johnson & Johnson, New Brunswick, NJ, 1897, pp. 6-7]

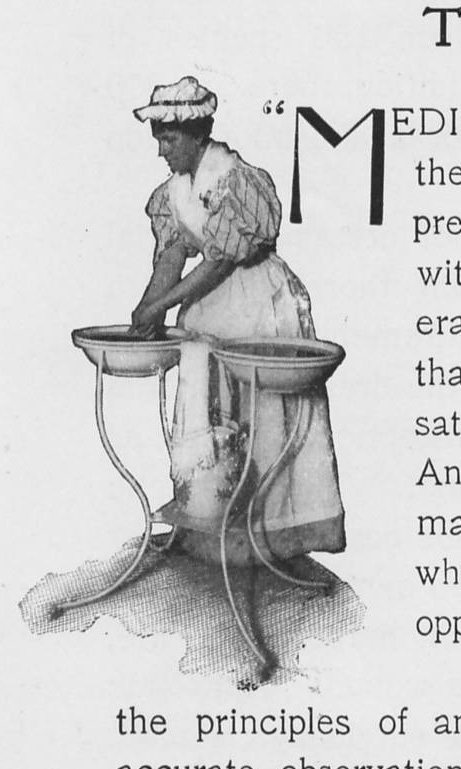

“Materials pass in and out of this room through a locking system that at once keeps out all dust and infection. The air of the room is filtered through cotton under pressure. Thus there is formed a perfect protective against dust and infection from without. The room is without apparatus or furniture, except for the necessary bowls for hand washing and for the care of washable uniforms, and white glass tables resting on enameled iron…” [RED CROSS NOTES, Series VI, No. 6, New Brunswick, NJ 1908, p. 127]

Aseptic Department Sinks

Aseptic Department employees had to wash their hands, arms and faces with antibacterial soap, and change into sterilized uniforms and caps before starting work. Employees from other departments and messengers were not allowed into the aseptic room, and visitors were only admitted by special permission of the office (which meant, most likely, that you had to gather up your courage and get your request okayed by Company founder Robert Wood Johnson), and only when under the direct supervision of the nurse in charge of the room. Visitors couldn’t “mingle with the operatives,” or employees, in the room and they weren’t allowed to touch anything. After each day’s work had concluded, all dressing materials and finished dressings were put away and a thorough cleaning was done. Clothing and other smaller items were sterilized in the big steam sterilizer. Tables, floors and other big things were dusted with a wet cloth, washed with antiseptic solution and then the entire room was closed and fumigated with sulfur and steam.

List of training course work and reading materials for Aseptic Department employees, 1897

So if you just followed all of those rules, you’d be all set to work in the Aseptic Department, right? Wrong. Employees involved in the making of the Company’s surgical dressings had to successfully pass a training course that included studying academic medical and scientific texts and reference books, answering questions and conducting experiments that educated them about the importance of preparing sterile surgical materials, the nature of the materials used in dressings and their preparation, how the dressings were used in surgery, how bacteria grew and multiplied, infection and disinfection, sterilization and aseptic techniques in the preparation of surgical dressings, and more. Fred Kilmer noted that the aseptic rooms were at all times under the direct supervision of graduate surgical nurses, and employees had to scrub in like modern surgeons every time they entered the aseptic room.

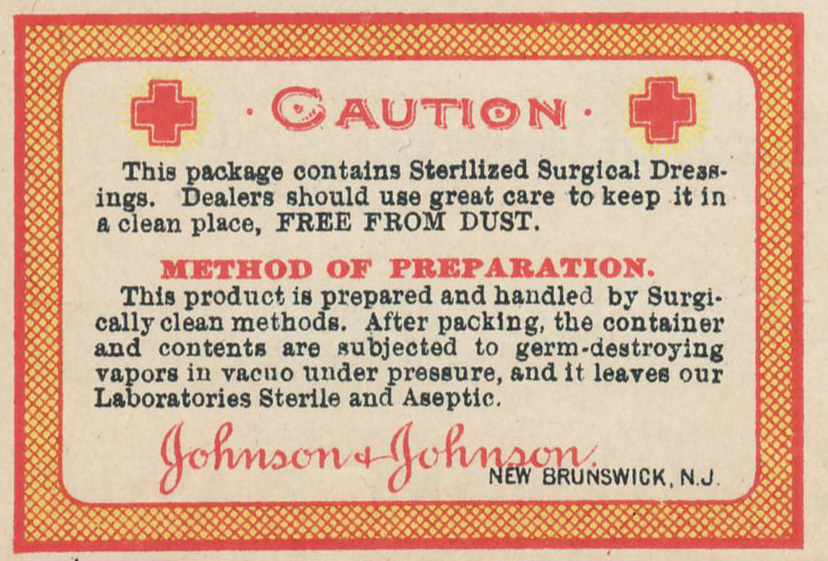

Aseptic Dressing Package Seal Signed by one of the Graduate Nurses, Elizabeth W------.

Illustration of Aseptic Room employee washing hands from 1897 Asepsis Secundum Artem (“According to the Art of Asepsis.”)

This detailed training and the Company’s strict requirements for manufacturing sterile dressings and sutures were in place at a time when many surgeons were still operating in their germ-covered street clothes, and Johnson & Johnson was rightly proud of its aseptic program, having pioneered these early clean room techniques.

The reason that Johnson & Johnson gave for taking such painstaking steps was that the dressings had to be perfect because lives depended on them, a responsibility the Aseptic Department employees took very seriously. As Fred Kilmer wrote in 1897, “The importance of the surgical dressing, the nature of its requirements, call for the greatest care.” [Asepsis Secundum Artem, Johnson & Johnson, New Brunswick, NJ, 1897, p 16]

You can still see one of the legacies of the Aseptic Department today, in the light, open design of buildings and interior spaces in the Johnson & Johnson Family of Companies throughout the world. The emphasis on bright white clean surfaces was absorbed by the future General Robert Wood Johnson and incorporated into our building designs worldwide…a very old tradition that we still follow to this day, over a hundred years later.

Then: white enamel and walls with lots of light…

Now: white buildings with lots of light

I really enjoyed this post. I imagine that the aseptic techniques used by JNJ at the time were more rigorous than the techniques used in most hospitals at the time.

It's easy to think that we are so much more scientifically precise about manufacturing techniques today than we were in the past, but this illustrates what could be done 120 years ago. I'm sure that modern techniques are even more strict today than back then, but I'd venture a guess that the techniques described here were quite adequate to prevent infection. Thanks for sharing this.