If A Train Leaves Chicago...

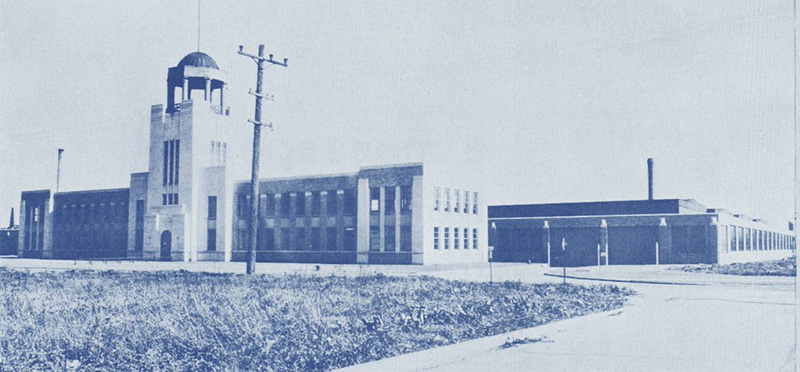

The old Temple Radio Plant in Chicago

It’s 1933 -- the depths of the Great Depression. The economy is struggling, the U.S. has a staggering 25% unemployment rate, and the New Deal legislation is in its early stages. Most of American industry is cutting back. But for Johnson & Johnson, it’s time to open a plant in Chicago.

Like everywhere else, Chicago had been hit hard by the Depression, but 1933 did hold some bright spots. Chicago’s Museum of Science and Industry opened in 1933. Chicago hosted the World’s Fair that year, highlighting a century of progress, and the first All Star baseball game was played at Comisky Park, with Lou Gehrig and Babe Ruth in the lineup. Ruth hit the first ever All Star Game home run, and his team won the game.

But, still…why did Johnson & Johnson open a major Midwestern plant during the worst of the Depression, and why in Chicago?

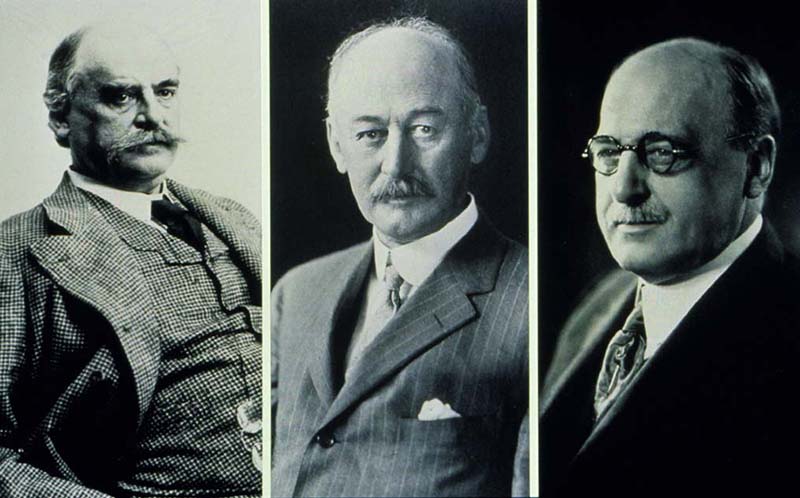

The founding Johnson brothers (from left, Robert Wood Johnson, James Wood Johnson, Edward Mead Johnson) who began the Company’s tradition of managing for the long term.

One of the many Johnson & Johnson traditions going all the way back to our founding in 1886 is prudent long-term management of the Company. As a result, Johnson & Johnson was able to not only weather the financial crises of 1893, 1907 and 1929, but it came out stronger each time. This philosophy was combined with the demand for the Company’s medical and consumer products, which had changed the way surgery was practiced and gave consumers a growing number of safe, reliable products they could use in the home. So although Johnson & Johnson did have to tighten its belt during the Depression, it was in a good position to continue its steady and responsible growth. Another big factor in the decision to open the Chicago plant was summed up best by Robert Wood Johnson: “…we were developing new ideas, new machines, new processes, new ways of doing things. These called for more than additional space; they demanded a new factory in which we could develop and test departures from old, established methods.” [Robert Johnson Talks It Over, Johnson & Johnson, New Brunswick, NJ, 1949, chapter 17, “Johnson & Johnson, Chicago”, p. 65]

Robert Wood Johnson, circa 1930s

Robert Wood Johnson, son of the founder by the same name, was in his second year of leading the Company. He was putting in place his philosophy of decentralization, which could be summed up as: “Be as local as you can be.” Johnson – and Robert Hayden, the Company’s vice president of manufacturing at the time -- wanted Johnson & Johnson to be seen as a local Midwestern business, part of the community there and not as some firm from back East that people really didn’t know all that well. Besides, Chicago was one of the country’s major railroad and highway hubs, which would help the Company ship its products out West much faster and more efficiently. The Company already had a small suture plant in Chicago, and the general manager of that plant was enlisted to help find a good location. I’ll let Robert Wood Johnson describe what happened:

“…sites and factories were easy to find, but we were planning for the future, not merely for 1933. We therefore continued our search until we found a location that would give us what we needed for many years to come. We discovered it in the Clearing Industrial District, a modern development in the southwestern part of Chicago. The site had plenty of space – several acres – and a good one-story factory with a fine, imposing entrance. There was also a modern office building that seemed to be just right for our needs.” [Robert Johnson Talks It Over, Johnson & Johnson, New Brunswick, NJ, 1949, chapter 17, “Johnson & Johnson, Chicago”, p. 66]

Our historic Chicago Operations

Here’s a picture of the site they chose. The main building was the former Temple Radio plant and you can see from that photo that it had great art-deco architectural features, including the “fine, imposing entrance” that so impressed Robert Wood Johnson.

Hundreds of unemployed Chicagoans lined up in front of the plant to find jobs, and a number of them were hired to work at the new Johnson & Johnson Family of Companies facility. When a brochure on the Chicago plant’s history was published in 1968, many of those Depression-hired employees were still there.

Nine Chicago employees in 1970 who were with the Company since the plant opened in 1933

The new Chicago plant proved to be so efficient that its first product line (MODESS® Sanitary Napkins) was in production just one month after workers were hired and the plant opened. During World War II, the Company’s Midwestern plant made an enormous contribution to the war effort, which was recognized by its earning of an Army-Navy “E” Award for Excellence. The plant also supported Bond Drives and other efforts during the war.

Employees in Chicago Celebrate Earning an Army-Navy “E” Flag During World War II

The Chicago facility lived up to its mission of providing a place to try new things, and it was one of the first Johnson & Johnson Family of Companies locations to enter the computer age in 1964 with the installation of a massive IBM computer with a card system. In 1967, that was upgraded to an IBM Model 360 Tape-Disk-Tele-Processing Computer that was dubbed a “miracle of electronics” because it could run three different programs at the same time. One of the things it did was run the quality control system, which became a standard for the Company and earned Johnson & Johnson a late 1960s recognition by the American Quality Control Association as a leader in the quality control field.

Part of the Chicago facility in 1968 – home to a “miracle of electronics” computer!

At its height, the Chicago operations occupied eleven buildings producing 492 products, with a major Midwestern shipping center for the Company. It was the site of many developments in engineering, operations, and quality assurance programs for Johnson & Johnson and it pioneered electronic records keeping for the Company – something we take for granted today, but which was new when it was introduced in Chicago over four decades ago -- with those room-sized computers.

That was a very interesting story, especially with today's unemployment concerns. Curious as to what happened to the plant and product lines?

I really enjoy these Kilmer House pieces. Thank you for writing them. I wonder why the entrance was "fine" because it was "imposing"? It is an interesting choice of words.

Brian,

I'm glad you like the blog! The choice of words was General Johnson's. He was a strong believer that manufacturing facilities as well as offices should be beautifully designed so that they were an asset to their communities, and so that employees would be proud to work in them. This philosophy found expression in his "Factories Can Be Beautiful" program, which led to many architecturally beautiful Company buildings around the world that were often mistaken for college campuses. Here's a post on the blog about that: http://www.kilmerhouse.com/?p=530

No doubt Johnson was attracted to the tower-like entrance with its art deco details.

Margaret

This is an excellent way to learn about Johnson & Johnson history. Very enriching and informative.

Will be good to let employees know the history of why and how Johnson & Johnson decided to invest outside US region eg. EMEA, Latin America and Asia Pacific? And any interesting development in these region?

Very inspiring histroy of company and future too

Dear Pang Chee,

Glad you like the blog! Johnson & Johnson has had a prsence in EMEA since the 1920s/1930s, Latin America since the 1930s, and in Asia Pacific since the 1930s and 1950s. I've done posts on the founding of our businesses in Canada (1919) and the U.K. (1924) and I certainly plan on doing posts about the origins of the businesses in other areas of the world as well, so please keep reading!

Margaret

This bought back many fond memories of my first years with J&J. I was hired as a college recruit from one of the state universitities. The facility was within 10 miles from my home on the South Side of Chicago.

I was there from 1974 to 1982. We were the largest manufacturing facility in J&J. We had great people, and manufacturured many of the J&J leading brands at the time - Band-Aid, Adhesive Tapes, Gauze Pads, Cotton Swabs, Cotton Balls. The facility was closed soon after I left.

Many of those employess still meet annually to renew friendships and revisit great memories of their time at MSDP (MidWest Surgical Dressing Plant)

Is the second plant picture the 65th street plant or as it was known as MSDP? The third plant picture looks like ESDP. Since it was 1968 is it the new diaper plant? I remember smelling the the "craker jacks" as you entered the 65th street plant. Fun to remember. Thanks

This brought back many fond memories of my first years with J&J. I was hired as a college recruit from one of the Illinois State Universities. The facility was within 10 miles of my home on the South Side of Chicago. By the way, the facility was a couple of blocks from Midway Airport.

I was there from 1974 to 1992 . We were the largest manufacturing facility in J&J. We had great people and manufactured many of J&J’s leading brands at the time- Band-Aid, Adhesive Tapes, Gauze Pads, Kling Bandages, Cotton Swabs, Cotton Balls. The facility was closed soon after I left.

Many of those great employees still meet annually to renew friendships and revisit great memories of their time together at MSDP (Midwest Surgical Dressings Plant)

David,

The bottom picture of the building from 1968 is the Midwestern Distribution Center. It does look a bit like ESDP. That was very much in the style of buildings the Company was building in that era. The historic art deco building faced West 65th Street, according to information in our archives, and an aerial photo I have identifies the whole complex as MSDP. If anyone can shed further light on that, please leave a comment.

Margaret

When I started my career with J&J in 1980, my aunt gave me a postcard dated September 1939 that is a picture of this facility. The Johnson & Johnson sing on the roof is much more basic than the picture above and on the right side of the entryway, the signage on the roof is "Surgical Dressings". Wondering if my postcard is an older picture than the one above? I am glad I kept this postcard after all these years as I now "have the rest of the story" behind this historic J&J building.

Roger

Great story. Very much liked Robert Johnson's statement 'keep everything as local as possible'.

During WWII the plant had a very interesting division there on 65th Street. Iw as the Gas Mask Division. They made gas masks for the military there. I am in possession of a Certificate of Award to my mother dated 3-22-1945 for the Army-Navy Production Award for Excellence in War Production. I also have numerous newsletters from 1944 called The Conveyor, which I assume was a company newspaper for J&J Gas Mask Division. I even have a much older one dated December 12, 1941 and it is called the J&J Gas-ette. It is just a 4 page newsletter but it is obvious that it was printed before knowledge of the Pearl Harbor attack less than one week earlier. If anyone would like some more info on these please contact me.

Gary,

Johnson & Johnson made a number of wartime products during the 1940s, including the gas masks in the Chicago plant. (We have one in our archives.) During World War II, American companies were called upon to make a variety of products specifically for the war effort, which was standard operating procedure in those days. I would love to have more information on your newsletters that your mother had saved. Feel free to email me through the blog. You can find a link to the email on the blog's "About the Author" page.

Margaret

I worked at the 65th St plant out of High School in 1974. Sad to see it's been torn down and replaced with a Marriot and such. I remember this plant wrapped around a Cracker Jack plant and had a railroad spur that was between it and it's warehouse plant off of 67th. This was a huge plant with numerous satellite cafeterias and various mills (3 as I remember it): Gauze, Cotton and Plaster. It was a maze of corridors , rooms, offices, Labs and storage areas. I worked the night shift and witnessed the activity that occured at the night time hours. I wish I would have documented this facility with photographs and notes from the day. I transferred out to the Joliet plant after a year or more and that location itself was quite a memory in itself. I was QA lab tech and got to see the facilities in their entirety at both plants. This was probably the best job I had in terms of interest. I could go into detail about what I saw as far as the R&D that was done at these plants.

Think the bottom photo is ESDP, the entrance at MDC was different. I drove passed ESDP for 7 years and if I missed a light I sat and looked at that view for what seemed like hours.

At it's peak MSDP stretched from 65th to 67th street with a covered aisleway across 66th. If you're aerial shows a parking lot on 67th street it is from 1970 or later.

The Midwest Diaper Plant (MDP) opened in '73. Somewhere I have 2 aerials of the construction. The original plan was to add it onto MDC as part of a plan to relocate all operatioms to Lemont. Quite a few diaper management people who bet on a location in the western suburbs ended up with a long commute.

One of those original mechanics (plant seniority #1) commuted, via public transportation without a single absence or tardy.

Lost a line in my earlier post.

He commuted from the far Northside of Chicago.

We were delighted to find this article, my grandfather is one of the original employees pictured. He retired in 1977(?)