The Company's Most Unusual Job Ever

What was the most unusual job in Johnson & Johnson history? Was it digging this tunnel? Working a gigantic printing press? Running a huge water filtration system? Making Mosquitoons? Or quality testing our short-lived cola tonic with the sherry base?

How about…glassblower.

Huh? We employed a glassblower? Well, actually…according to our records, we employed nine glassblowers. And it had to do with the Company’s manufacture of sterile sutures and ligatures for surgery.

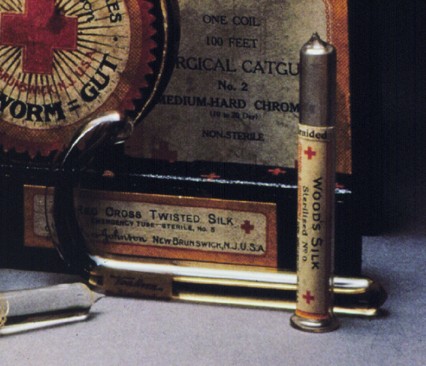

These are some of the sterile sutures and ligatures made by Johnson & Johnson almost 100 years ago, packaged in glass tubes…made by Company glassblowers.

At the time, Johnson & Johnson wasn’t just the largest producer of sterile surgical dressings in the world, it was also the largest manufacturer of catgut ligatures in the world, producing an astounding 10 million feet per year. A retail druggist visiting Johnson & Johnson in 1917 toured the Company’s ligature laboratory, which operated under the strictest antiseptic conditions. He watched the raw materials being cleaned and sterilized (employees in the department explained to him that full cleaning took about a week) and chromicized, which was the process of waterproofing the catgut so that it wouldn’t be absorbed by the body for a set period of time.

To insure the quality of its ligatures -- because the lives of surgical patients depended on them -- the Company performed every step of the manufacturing process with minute detail. The druggist commented “…I noticed that no detail is so slight that it can be neglected in the Johnson & Johnson laboratories.” [THE RED CROSS MESSENGER, January 1917, Vol IX, No. 4, p. 107]

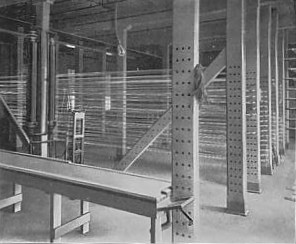

Ligatures Being Dried

After the chromicizing process, the raw material was twisted into strands by machine and then dried, after which the strands were smoothed and polished. They were sorted by size and then tested for strength, which was important because it insured consistency – that each container of sutures or ligatures was exactly the same quality as all of the others.

“When the surgeon gets a strand of Johnson & Johnson catgut he knows exactly the pulling it will stand before it snaps. The smallest strand, twelve-thousandths of an inch, will stand five pounds, and the largest, thirty-six thousandths of an inch, will stand fifty pounds. They have to come up to that standard or they are rejected.” [THE RED CROSS MESSENGER, January 1917, Vol IX, No. 4, p. 108]

The ligatures were then cut into various lengths and sterilized again. Here’s where the glassblowers came in. Let’s quote our druggist again:

“In the meantime the glassblowers are busy in a nearby department. These skillful men are blowing and shaping glass containers. Under the influence of their deft fingers glass assumes many fanciful shapes. It takes nine of them to keep up with the demand, and they turn out many thousands a day.” [THE RED CROSS MESSENGER, January 1917, Vol IX, No. 4, p. 109]

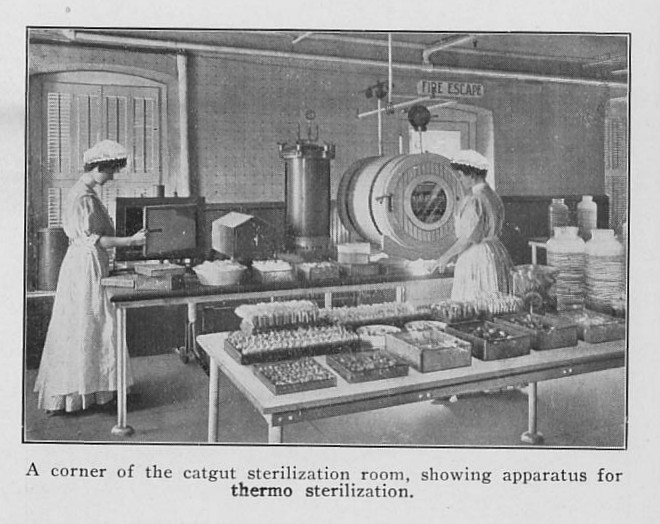

The Catgut Sterilization Room, 1917

When the ligatures came out of the sterilizer, they were placed in the glass containers by workers wearing sterilized rubber tips on their fingers, and working on glass-topped tables – because the glass could be kept germ-free. The tubes were corked and sent back to the glassblowers, who sealed them. The sealed package was sterilized yet another time and was then considered “ready for the surgeon.”

When each batch of ligatures was finished, a sample package was chosen at random, opened and tested by scientists in the Company’s bacteriological laboratory. Here’s the description of the testing given by the visiting druggist:

“The chemists open a package from each lot, using the same precautions in handling it as should be taken in a hospital. They remove the ligature strand with sterile forceps, and then conduct a check-test to determine if the sample is sterile. These tests run into the many thousands and are the most perfect known means to check the efficiency of the sterilization process. The chemist not only puts a label on the batch of strands from which he has tested samples, certifying that they are sterile, but he must sign his report in the record book. Johnson & Johnson intend that ligatures shall reach the surgeon in a perfect condition and surgeons have told me that they do. [THE RED CROSS MESSENGER, January 1917, Vol IX, No. 4, p. 109]

After taking such painstaking care to make sure that every ligature was sterile, uniform and trustworthy, the Company wasn’t about to leave the packaging to chance. It had to be done to the same exacting specifications….which is why we had such an unusual job as glassblower at Johnson & Johnson almost 100 years ago.

Sterile Suture or Ligature package -- Made by Johnson & Johnson Glassblowers

Margaret,

Really great article on a very important topic! I am in R&D at Ethicon and work with the current packaging materials and processes. Is there any way to get a better resolution image of the vial packages?

Thank you!

Ray

Ray,

I'm glad you liked the post! Those may be the only images we have of the handblown glass packaging. I haven't seen another one, but if I find a better photo, I will post it on the blog or send it to you.

Margaret

Thank you so much for this website! It is absolutely facinating and I've learned so much about the company I work for. I'm honored to be a J&J employee!

These are very interesting articles. Please keep them coming.

It's simply fascinating Margaret.

I can feel the presence of the past!

Thank you Margaret for bringing to us the sense of the past..

The beginnings of Johnson & Johnson and

the zeal of the Great General Robert Wood Johnson.

Margaret -

Thank you for the article on catgut suture production and employment of glassblowers for packaging of sterile suture.

As a medical sales person for J&J the last 9 years, I have worked to provide instruction on the safe and efficacious use of our products. I am curious, how did the circulating operating room nurse open the glass tube to pass off the suture?

Thanks, Dave

Hi Dave,

I looked that up for you, and found an answer in a 1908 edition of RED CROSS NOTES, which was a Johnson & Johnson publication for doctors, surgeons and nurses. The glass tubes were constructed so that the end could be safely removed by tapping it lightly with tweezers or scissors.

Margaret

Margaret - keep finding and publishing these interesting articles from our past. Nice work.

- Brian

All,

Love history in general and it's even more fun to hear it about J&J. Is this published anywhere at corporate offices? It'd be a fun booklet or book to read. Might be a great retirement type of gift to give.

Keep the articles coming.

-Perry

Ethicon Endo-Surgery/Breast Care

Margaret,

Loved the article. I loved going to the museum and live the past thru the photographs and antiques.

I was sad to see the Kilmer house (the tall building which is now the parking lot in front of Johnson Hall) come down. But now I am glad you are keeping the old alive.

Thanks for your interest and sharing.

Radhika

MMM, What a wonderful article. Our attention to detail and quality is what has makes us such a great company and one I am proud to be a part of. Thanks for sharing

Gita

This was really interesting.

Living in today's society, I think we take for granted all the manual labor that went into producing products, let alone sterile products, in a uniform manner. And not just the care in producing the products, but also the perfect packaging. It seems that they would have required more than nine glassblowers.

Margaret,

How long did J & J produce the catgut suture material in the glass blown tubes?

Randal

In reply to Margaret,… by Anonymous

Hi Randal,

The company produced sutures in tubes for many decades. The glassblowers would have been earlier, but we don't have additional information.

Margaret